[ad_1]

Aaron Wilson, Flexco, considers preventative conveyor upkeep measures that scale back downtime and optimise processes.

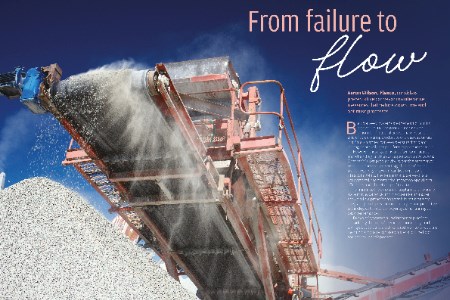

Belt conveyor techniques are the center of mining operations. By consistently pumping huge quantities of fabric throughout large websites, and effectively delivering product to end-use prospects in a well timed method, conveyors make sure that plant managers truly receives a commission for the roles they tackle.

Nevertheless, these techniques are sometimes difficult, and after they fail, the implications may be extreme. Whether or not it’s misplaced productiveness, costly emergency repairs, or the ever-present vital security danger, a sloppy conveyor system may be the foundation of a website’s ache factors. The longer {that a} conveyor sits unaddressed, the higher the impression on operational effectivity, and, subsequently, profitability.

To minimise the quantity of unplanned downtime a website might expertise, mining operation managers ought to take a proactive strategy to upkeep, integrating each preventative methods and predictive applied sciences to maintain conveyor techniques operating at peak efficiency.

By exploring important upkeep practices, contemplating the position of predictive monitoring, and taking steps to construct a well-tailored upkeep plan, the mining business can preserve materials off the ground and cash of their pockets.

Key preventative upkeep practices for mining conveyor techniques

Implementing routine upkeep is crucial for extending conveyor tools lifespan, bettering operational effectivity, and decreasing general downtime.

Specializing in high-impact areas like belt cleaners, limitless splicing and mechanical belt fastening techniques, and key belt switch factors helps to make sure that the conveyor system can proceed to function easily below such harsh mining circumstances.

Getting began with constructing a plan may be essentially the most difficult half, however by homing in on these areas, website managers can extra simply restrict their maintenance-related downtime.

Belt cleaner upkeep: The primary line of defence

Probably the most frequent causes of fabric buildup and conveyor inefficiency is an improperly maintained belt cleaner. Over time, carryback – the residual materials left on the belt after discharge – accumulates, resulting in extreme spillage, belt mistracking, and elevated put on on system parts. If left unaddressed, this may end up in operational slowdowns, elevated cleanup efforts, and even compliance points with regulatory companies.

Nevertheless, by incorporating routine belt cleaner inspections, mining operations can considerably scale back these dangers and enhance general system efficiency.

A crucial a part of sustaining belt cleaners is guaranteeing correct tensioning. Common changes permit the cleaner to keep up constant contact with the belt, maximising its means to take away residual materials successfully. With out this routine tuning, a cleaner might both press too flippantly, permitting materials to cross by means of, or too firmly, resulting in untimely blade put on and potential belt injury.

Worn-out cleaner blades are one other frequent situation, as uninteresting or broken blades scale back scraping effectivity, permitting extra carryback to flee. Not solely does this contribute to materials loss, but it surely additionally creates upkeep challenges as spilled materials accumulates across the conveyor system, exposing staff to dangerous airborne mud, and creating a multitude that staff must clear.

This can be a preview of an article that was initially revealed in Problem 1 of World Coal 2025.

Subscribe to World Coal totally free to learn this text in full and lots of extra here.

Learn the article on-line at: https://www.worldcoal.com/coal/16072025/from-failure-to-flow/

[ad_2]

Source link